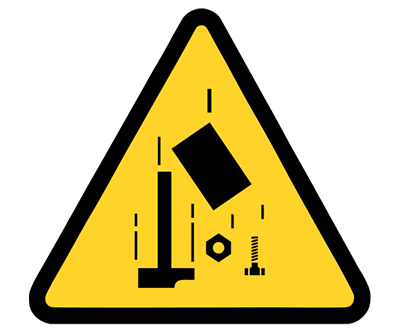

Dropped Objects

Posted: Feb. 25, 2020 • By Kevin Kohler

Are dropped objects much of a concern?

Dropped objects don’t sound very dangerous but they have been a long-standing concern at workplaces; particularly in the construction sector, where people and equipment often work at various levels and on top of each other. Despite many years of attention focused on this hazard, and numerous campaigns to resolve the problem, it is still a major concern.

Consider the information from a press release by the International Safety Equipment Association in the U.S:

Falling and being struck by a dropped object are among the top causes of workplace injuries and fatalities:

- (The Bureau of Labor Statistics) BLS reported that being struck by falling objects or equipment resulted in 45,940 injuries in 2017 (5.2% of all workplace injuries).

- According to (OSHA) dropped objects are the third leading cause of injuries in construction.

In Canada, the Ontario Workplace Safety and Prevention Services states that 27,000 workplace incidents involving dropped objects are reported to Canada’s workers compensation boards each year. The problem is not necessarily improving, with the BLS reporting increases in deaths and injuries from dropped objects, in recent years.

What if it’s just a small item that fall?

It can be difficult to imagine how a small object can result in severe injury. A dropped object can acquire a great deal of energy in a short period of time as its velocity accelerates. According to the Dropped Objects Prevention Scheme (DROPS), an oil and gas industry initiative to prevent dropped objects, even small weights of 300g, dropped from a sufficient height, have enough energy to cause a debilitating injury to a worker wearing PPE, such as a hard hat.

Why do so many objects fall?

Objects fall at work due to:

- A lack of training and awareness of the potential hazards

- An emphasis on signage, barriers and netting rather than eliminating the hazard at its source

- Inadequate procedures, equipment and training to mitigate for dropped objects

- Hazards and risks that are not fully assessed before beginning work

- Lack of incident reporting, monitoring and follow-up

Any unsecured item such as tools, radios, PPE, parts and equipment, loose materials, flashlights, liquids, etc. can fall and cause injuries.

What specific controls can I use?

The Ontario Infrastructure Health and Safety System has identified physical and procedural controls to prevent objects from hurting workers. Physical controls include:

- Guardrails with toe boards or screening

- Covers on open grating

- Barricades and overhead protective structures

- Tool lanyards and tethers

Procedural controls include:

- Proper load securement and hoisting practices

- Housekeeping practices

- Proper storage and stacking of materials

The hierarchy of controls must always be considered when establishing hazard controls, with elimination or engineering being the preferred control, rather than relying solely on PPE or administrative controls such as signage.

What are some best practices to prevent dropped object injuries?

Dropped object hazards must be included in your hazard identification process. If dropped object hazards are present they must be evaluated using your hazard and risk assessment procedures and, whenever it is reasonably possible, the hazards should be controlled at their source.

Formal dropped object control programs, such as through DROPS, can be adopted. You may want to verify that your safety devices comply with the ANSI/ISEA 121-2018, “American National Standard for Dropped Object Prevention Solutions”. This standard establishes minimum design, performance, and labeling requirements for solutions and testing of active controls that mitigate dropped object hazards. These controls include: anchor attachments, tool attachments and tethers and containers. We need to renew our emphasis on the hazards of dropped objects in order to help us protect workers and prevent avoidable injuries.

Related Articles

Purging to Control Explosion Hazards

What is purging? Industrially purging refers to removing flammable gases and vapours by replacing them with a non-flammable substance. Purging […]

Read Article

Controlling Blood-Borne Disease in the Workplace

What are blood borne diseases? Blood-borne diseases result from exposure to micro-organisms (pathogens) that are present in human blood. The three […]

Read Article